The tabs are working. Please, note, that you have to add a template to the library in order to be able to display it inside the tabs.

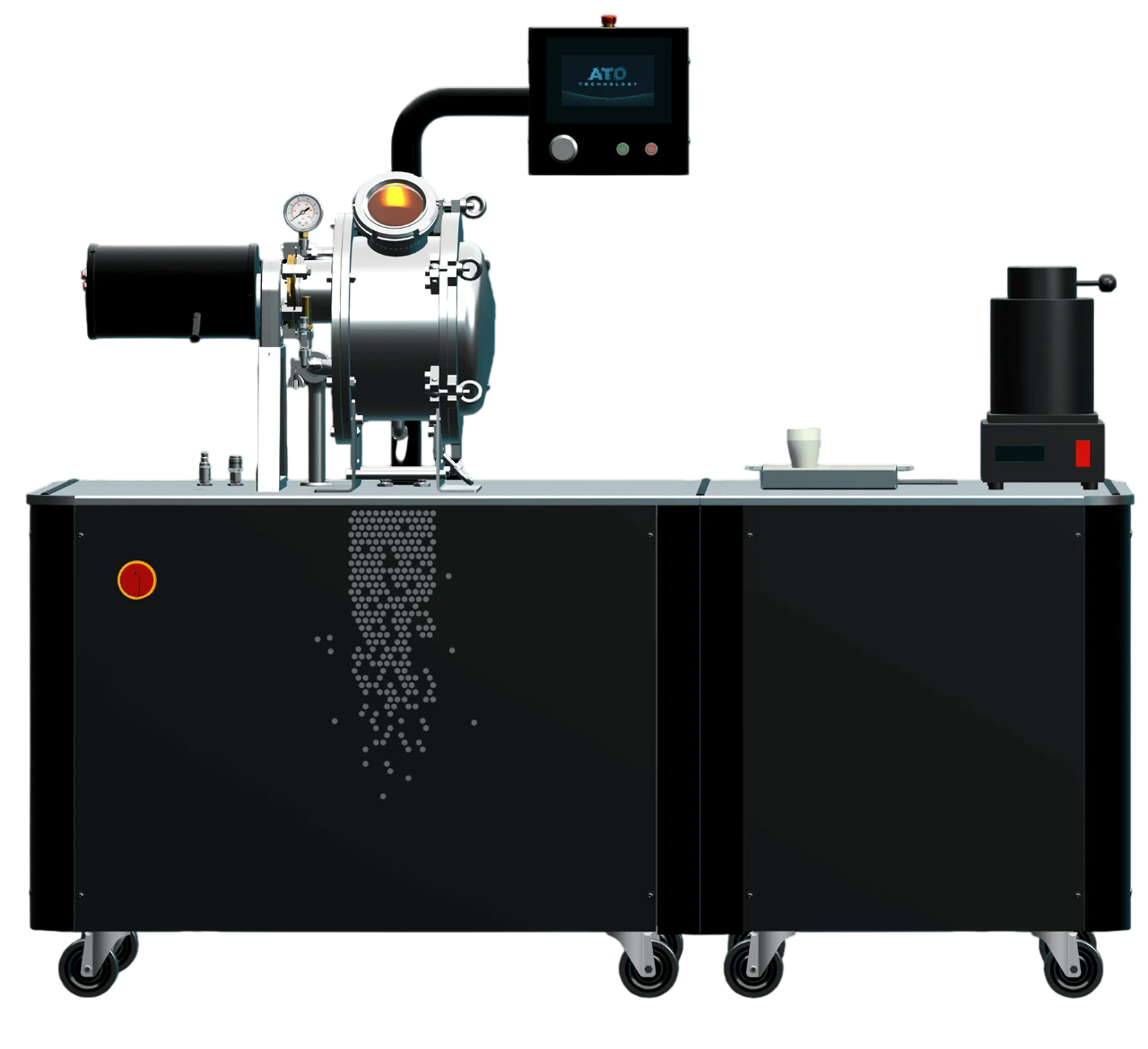

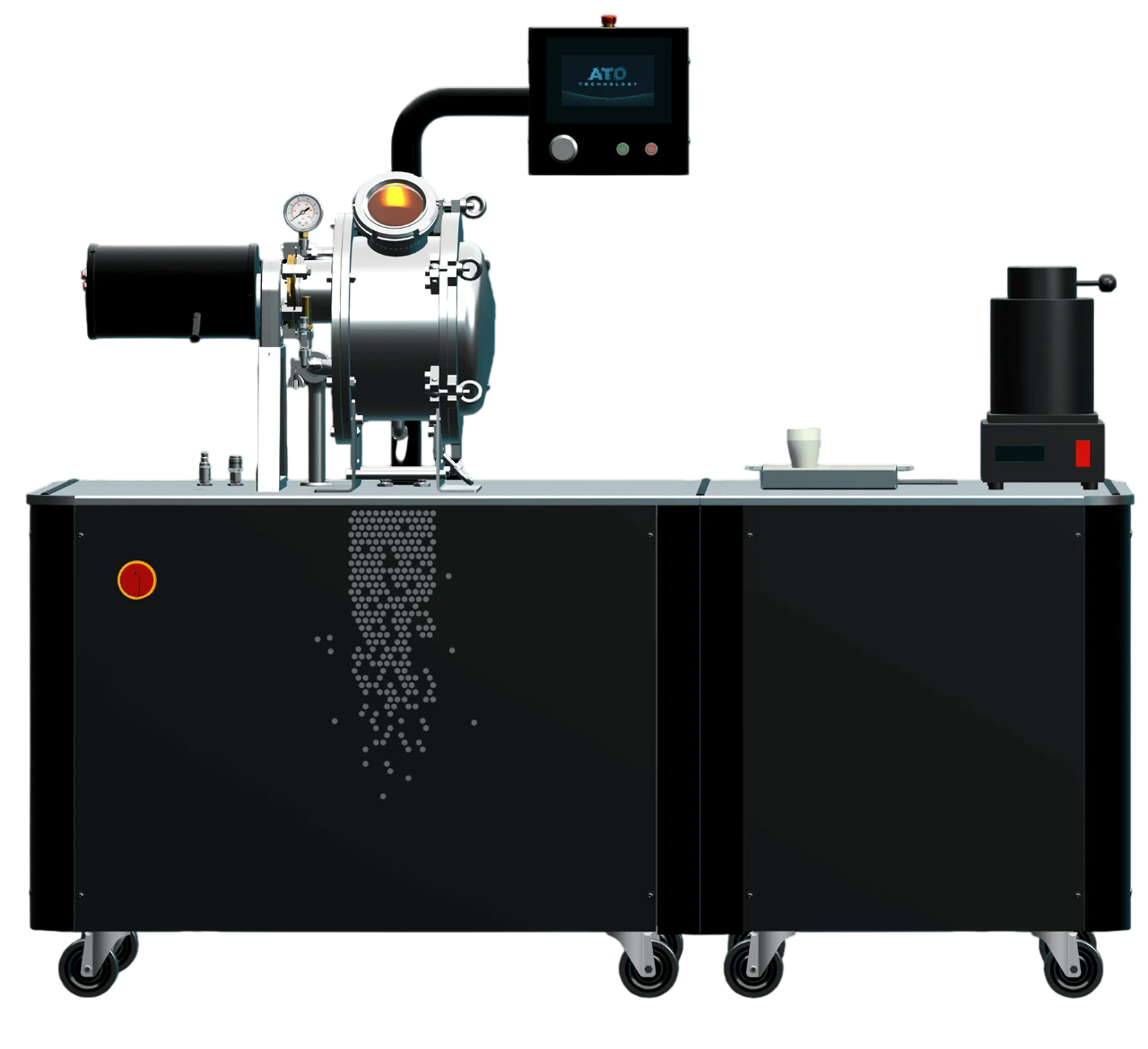

ATO Cast Induction Vacuum Casting Furnace

The ATO Cast is a state-of-the-art induction vacuum casting furnace engineered for high-purity metal feedstock production. It employs induction heating within a vacuum environment to melt and cast alloys, ensuring minimal contamination and oxidation. This process is particularly advantageous for producing high-quality rods from various metal compositions.

Key technologies include:

-

Induction Heating: Utilizes electromagnetic induction to heat and melt metals efficiently.

-

Vacuum Environment: Maintains a controlled atmosphere to prevent oxidation and contamination during melting.

-

Integrated Sensors: Equipped with an oxygen sensor and pyrometer with live camera monitoring for real-time process control.

-

Modular Design: Compatible with ATO rod-feeding systems, allowing flexibility in alloy development and material recovery.

These features collectively enhance the furnace’s capability to produce high-purity metal rods suitable for various applications, including additive manufacturing and material research.