Behind every finely crafted jewelry piece lies a sophisticated process that merges art, engineering, and precision casting. Among these techniques, Lost Wax Casting remains the most accurate and reliable method for reproducing intricate metal designs. At the heart of this process stands the Wax Tree – a carefully engineered structure that organizes multiple wax models for efficient batch casting.

A well-constructed wax tree ensures proper metal flow, uniform cooling, and consistent casting quality. In essence, it is the backbone of high-volume, high-precision jewelry production. This article explores the wax tree’s structure, fabrication methods, and how modern technology is transforming this ancient craft.

What Is a Wax Tree?

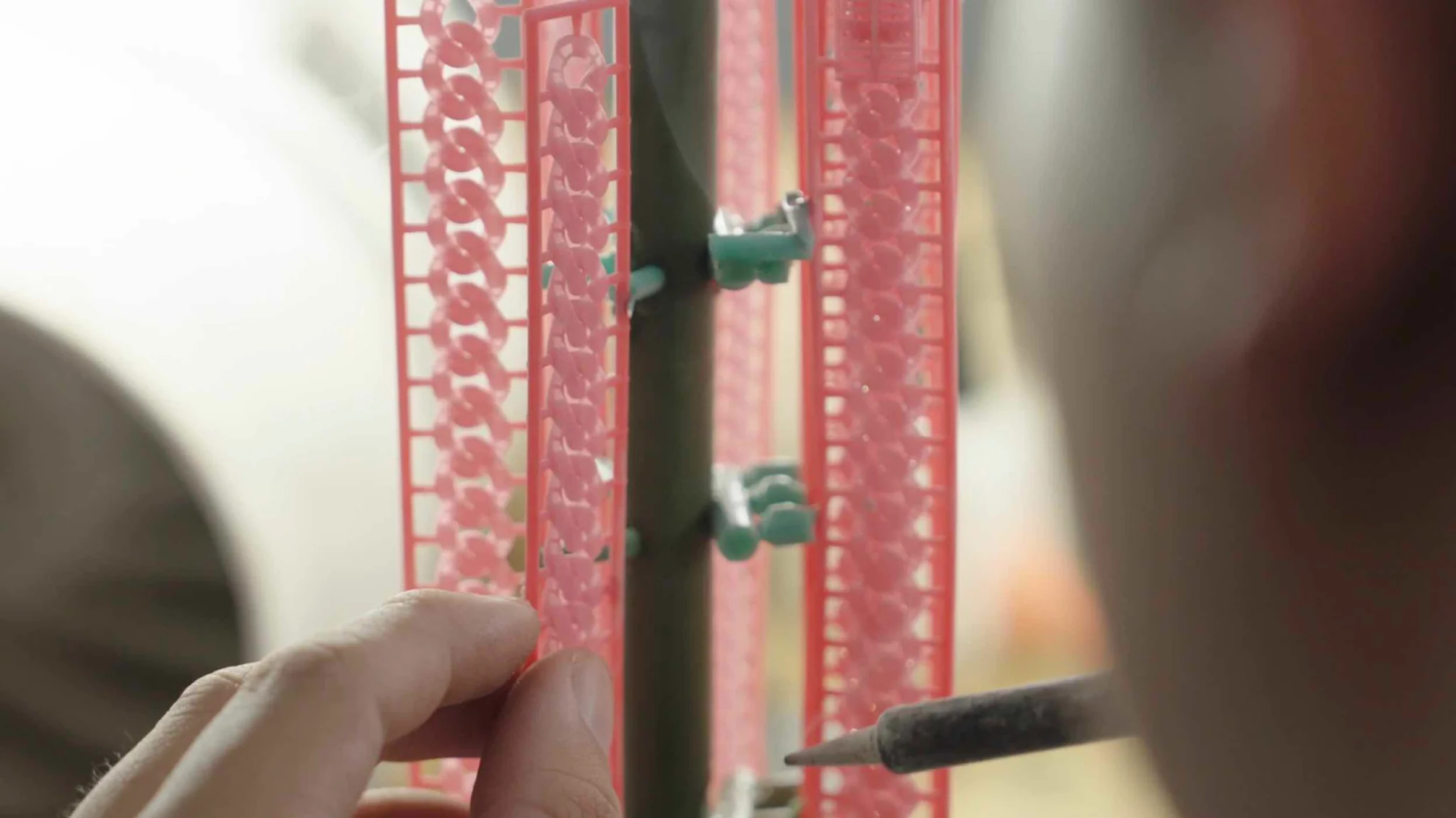

In lost wax casting, a wax tree (or casting tree) is a tree-like assembly made by connecting multiple wax models to a central sprue. Each “branch” holds a wax pattern that becomes the mold for an individual jewelry piece. The completed tree is encased in refractory investment material, then heated to melt out the wax – hence “lost wax” – creating perfect cavities for molten metal.

This intelligent design serves as a micro-scale distribution system that:

-

Controls metal flow throughout all branches

-

Ensures proper air venting to prevent porosity

-

Maintains thermal balance for even solidification

-

Enables batch production of multiple pieces

From Traditional Craft to Digital Precision

While many workshops still rely on manual “wax tree planting” by skilled artisans, modern jewelry manufacturing is embracing digital solutions. Traditional methods, though flexible, often involve:

-

Time-consuming hand assembly

-

Inconsistencies between different operators

-

Limited design complexity

-

Higher risk of human error

Today, advanced 3D printing technology from Flashforge offers a revolutionary alternative. Using MJP (MultiJet Printing) wax printers, manufacturers can now produce complete, optimized wax trees directly from digital designs.

Key Advantages of 3D Printed Wax Trees:

Precision Engineering

-

Perfectly calibrated sprue diameters and branch angles

-

Consistent wall thickness throughout the structure

-

Optimized metal flow channels based on computational fluid dynamics

Unmatched Efficiency

-

Print complete trees in hours rather than assembling them over days

-

Eliminate manual welding and positioning errors

-

Produce complex geometries impossible to create by hand

Material Excellence

Flashforge’s specialized casting wax materials offer:

-

High resolution for intricate details

-

Clean burnout with minimal residue

-

Excellent surface quality reducing post-processing

Design Freedom

-

Create optimized branching patterns for specific metal types

-

Incorporate ventilation channels and pressure relief features

-

Scale production with identical quality every time

The Future of Jewelry Manufacturing in Armenia

At 3D Print, we’re bringing this technology revolution to Armenian jewelry makers. The Flashforge WaxJet series enables local artisans to:

-

Reduce production time from weeks to days

-

Minimize material waste through optimized designs

-

Achieve consistent quality across production runs

-

Compete globally with world-class precision

Whether you’re creating delicate filigree work, modern geometric designs, or traditional Armenian patterns, 3D printed wax trees maintain every detail with perfect fidelity.

Ready to Transform Your Production?

The transition from manual wax tree assembly to digital manufacturing represents more than just efficiency – it’s about achieving new levels of artistry and precision. As Armenia’s leading provider of additive manufacturing solutions, we’re here to help you navigate this transformation.

Contact 3D Print today to learn how Flashforge wax printing technology can elevate your jewelry production while maintaining the craftsmanship that defines Armenian artistry.

Explore our range of Flashforge WaxJet printers and discover how digital precision can enhance traditional craftsmanship.